The Silent Sentinel: A Deep Dive into the Inner Workings of a Modern Sewage Treatment plant

Beneath the mundane surface of our daily lives, a complex and vital process unfolds: the treatment of wastewater. Sewage treatment plants, often relegated to the periphery of our awareness, stand as silent sentinels, safeguarding public health and environmental integrity. This 3000-word exploration delves into the intricate mechanisms of a modern sewage treatment plant, unraveling the journey of wastewater from its arrival to its eventual release as treated effluent.

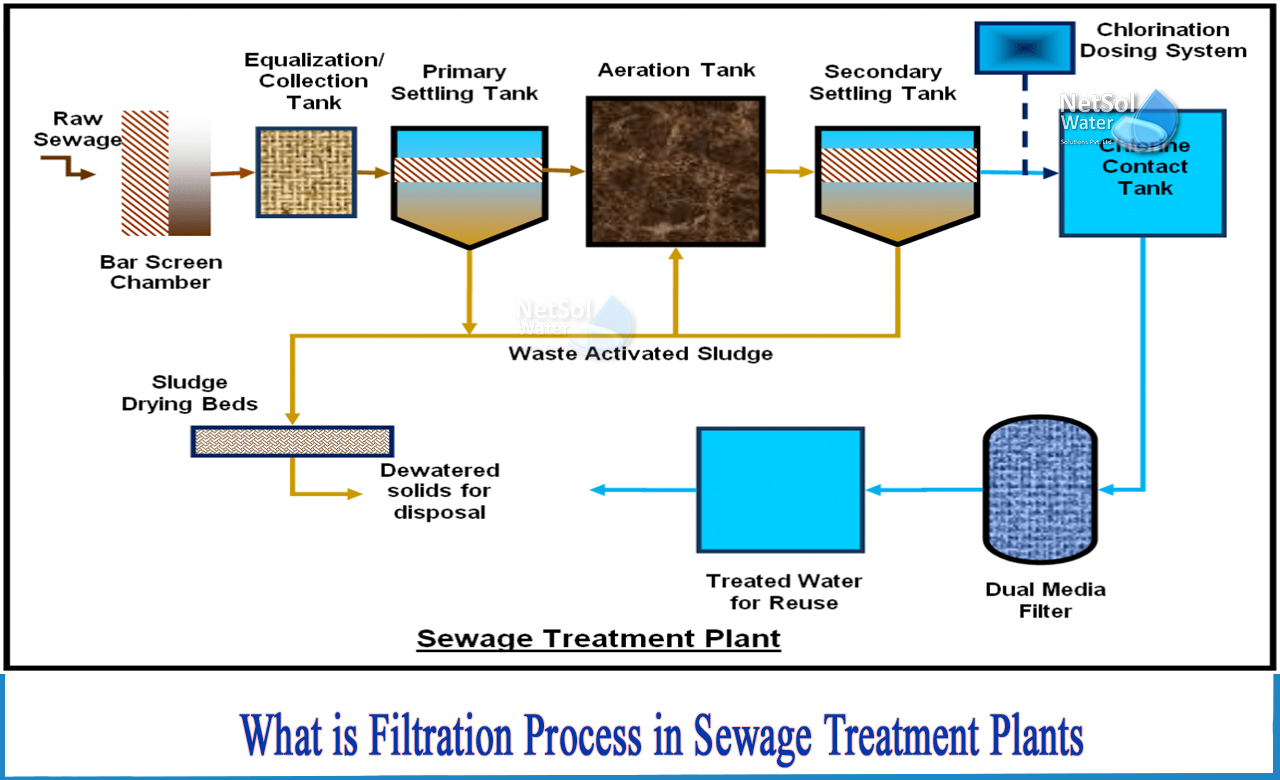

The journey begins with the arrival of raw sewage, a heterogeneous mix of domestic, industrial, and sometimes stormwater runoff. This initial influx, carried through a network of underground pipes, presents a daunting challenge. The composition of sewage varies significantly, influenced by factors such as population density, industrial activity, and weather patterns.

Preliminary Treatment: Removing the Gross Solids

The first stage, preliminary treatment, focuses on removing large, easily separable solids. This process protects downstream equipment and ensures the efficiency of subsequent treatment stages.

Screening

Coarse screens, typically bar screens with wide spacing, intercept large debris such as rags, plastics, and wood.

Grit Removal

Grit chambers, designed to slow the flow of wastewater, allow heavier inorganic solids like sand, gravel, and coffee grounds to settle out.

Flow Equalization

Flow equalization basins are used to regulate the flow of wastewater, preventing surges that could overwhelm downstream treatment processes.

Primary Treatment: Settling and Separation

Following preliminary treatment, the wastewater enters the primary treatment stage, where the focus shifts to removing settleable solids and floatable materials.

Primary Sedimentation Tanks

Large, circular or rectangular tanks, known as primary clarifiers, allow gravity to settle out suspended solids.

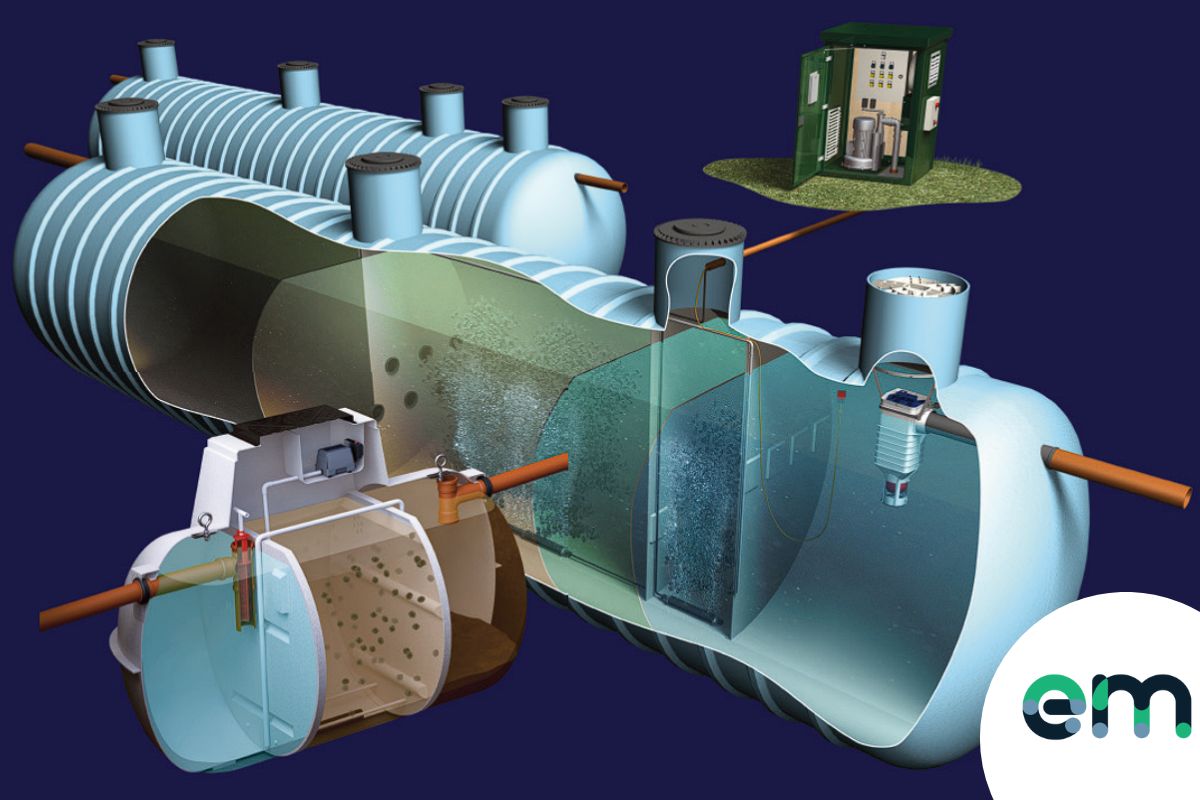

Secondary Treatment: Biological Breakdown

The heart of the sewage treatment process lies in secondary treatment, where microorganisms play a crucial role in breaking down organic pollutants.

Activated Sludge Process

The most common secondary treatment method, the activated sludge process, involves introducing air into a tank containing a mixture of wastewater and microorganisms (activated sludge).

Secondary Clarifiers

In secondary clarifiers, the activated sludge settles out, forming a dense layer at the bottom of the tank.

Trickling Filters

An alternative to the activated sludge process, trickling filters consist of a bed of rocks or plastic media over which wastewater is sprayed.

Membrane Bioreactors (MBRs)

MBRs combine biological treatment with membrane filtration, offering a more compact and efficient treatment process.

Tertiary Treatment: Advanced Purification

In some cases, secondary treatment alone may not be sufficient to meet stringent effluent quality standards. Tertiary treatment, also known as advanced treatment, provides an additional level of purification.

Disinfection

Disinfection is essential to eliminate pathogenic microorganisms, such as bacteria and viruses, from the treated effluent.

Nutrient Removal

Nutrient removal processes are used to reduce the levels of nitrogen and phosphorus in the effluent, preventing eutrophication in receiving waters.

Filtration

Sludge Treatment and Disposal: Managing the Byproduct

The treatment of sewage generates a significant amount of sludge, which requires careful management and disposal.

Sludge Thickening

Anaerobic Digestion

Anaerobic digestion involves the breakdown of organic matter in the sludge by microorganisms in the absence of oxygen.

Sludge Dewatering

Sludge dewatering processes, such as centrifugation or belt filter pressing, further remove water from the sludge, producing a drier cake.

Sludge Disposal

The final disposal of sludge must comply with environmental regulations.

The Outflow: Treated Effluent and Environmental Stewardship

The culmination of the sewage treatment process is the discharge of treated effluent into receiving waters, such as rivers, lakes, or oceans.

Effluent Monitoring

Stringent monitoring of effluent quality is essential to ensure compliance with environmental regulations.

Environmental Stewardship

Modern sewage treatment plants are increasingly focused on environmental stewardship, minimizing their environmental footprint and promoting sustainable practices.

The sewage treatment plant, a complex and often overlooked infrastructure, plays a critical role in protecting public health and the environment. Through a series of intricate processes, wastewater is transformed from a potential hazard into a valuable resource, ensuring the sustainability of our water resources and the well-being of our communities. As technology advances, sewage treatment plants will continue to evolve, becoming more efficient, sustainable, and integrated into the urban water cycle.